Make a CNC machine from old printers

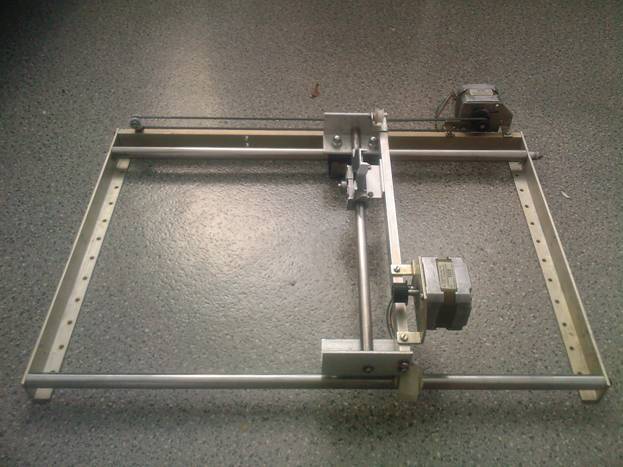

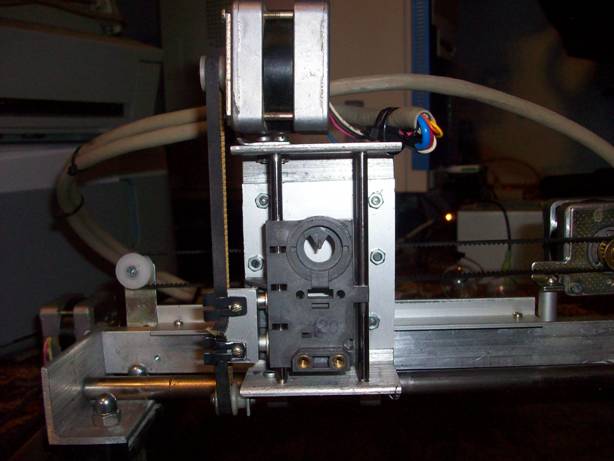

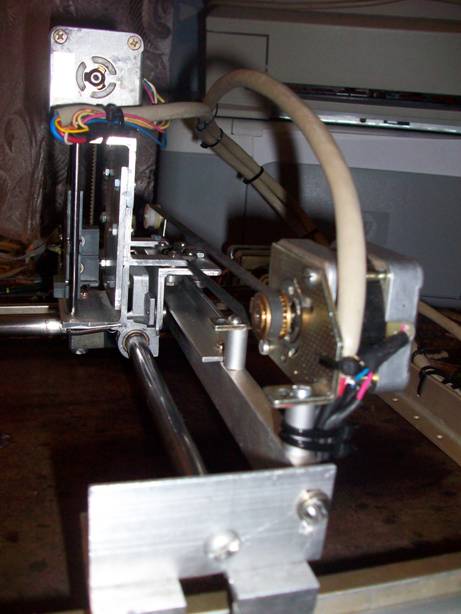

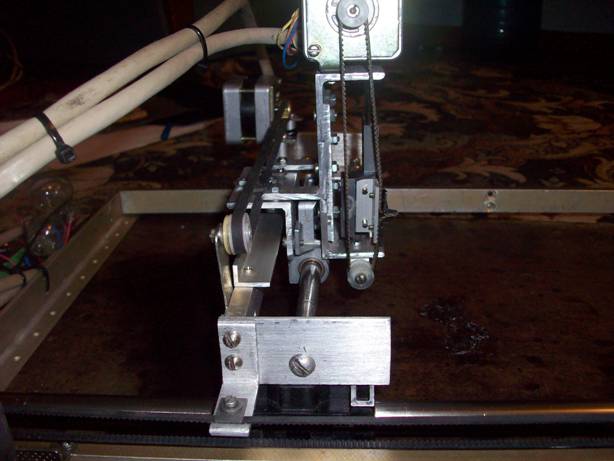

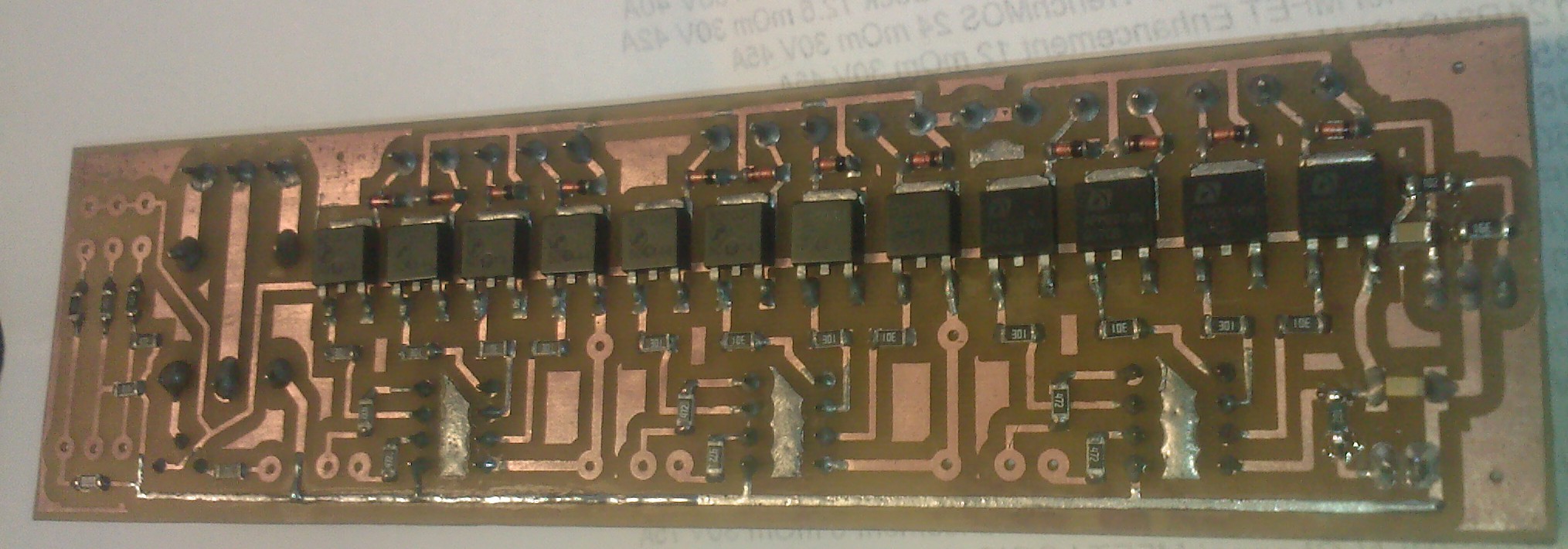

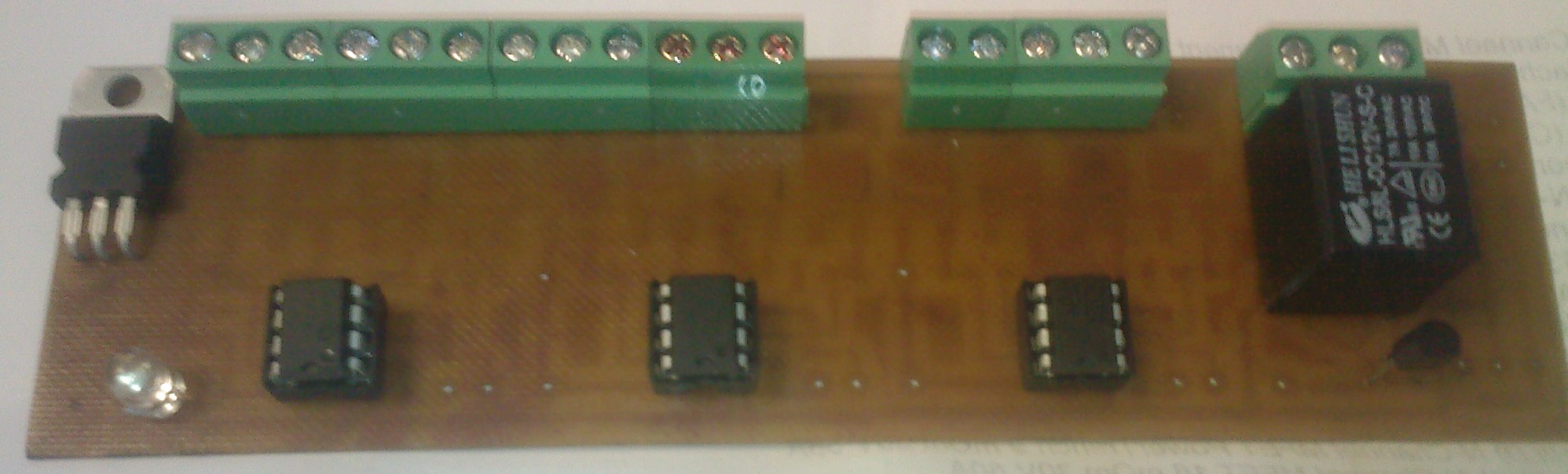

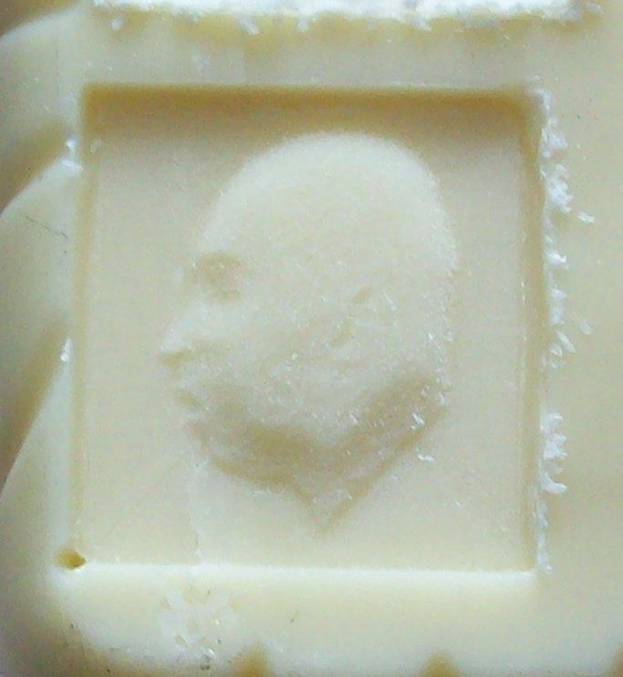

Printers are retrieved from the rails, a carriage with bearings, stepper motors, toothed belts and gears. Using the aluminum bath, intends to frame the future of the CNC machine. Attach a frame to the base of chipboard or other suitable material. The base must be rigid and heavy    Z coordinate is made from the remains of 5-inch floppy disk (using the guides and bearings) and aluminum corners. Mechanics ready.   To revive the machine, you need a stepper motor controller. He also assembled using parts from old computers.The controller supports only half-step mode. Feeding all the electronics made from the computer power supply. The CNC machine is made exclusively for burning and paint marker, but later wanted to try something more serious.    To prepare the following programs were used ArtCAM 2008, Autodesk 3ds Max, Gcode 2000. Disadvantages of CNC machine: Need to continually tighten belts (stretch) Z coordinate of the FDD weak for milling, rapid deterioration. Ярлыки: Make CNC |

Comments on "Make a CNC machine from old printers"

post a comment